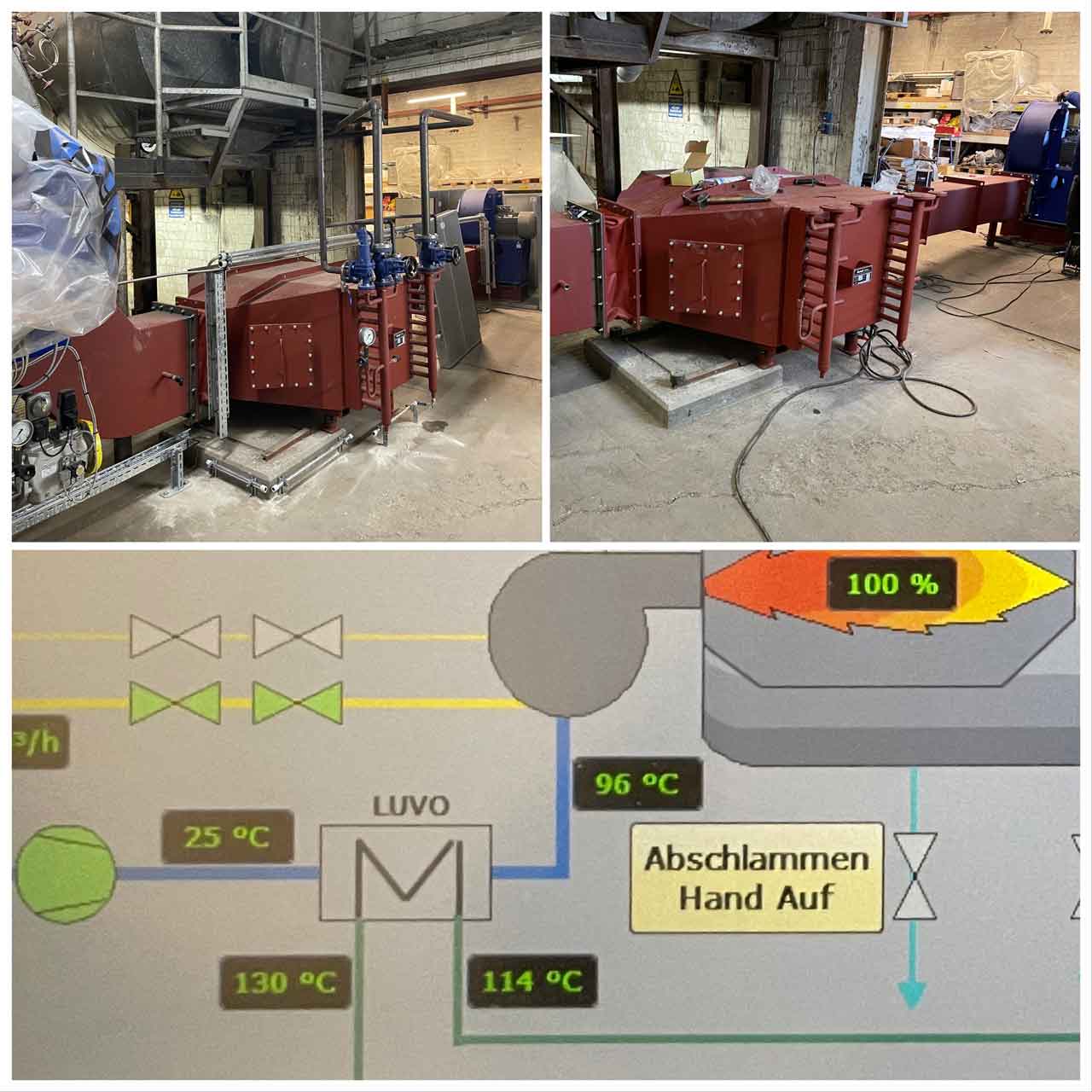

Combustion air preheater for building material industry

Engineering, manufacturing and assembling of a heatexchanger with power of 210 KW

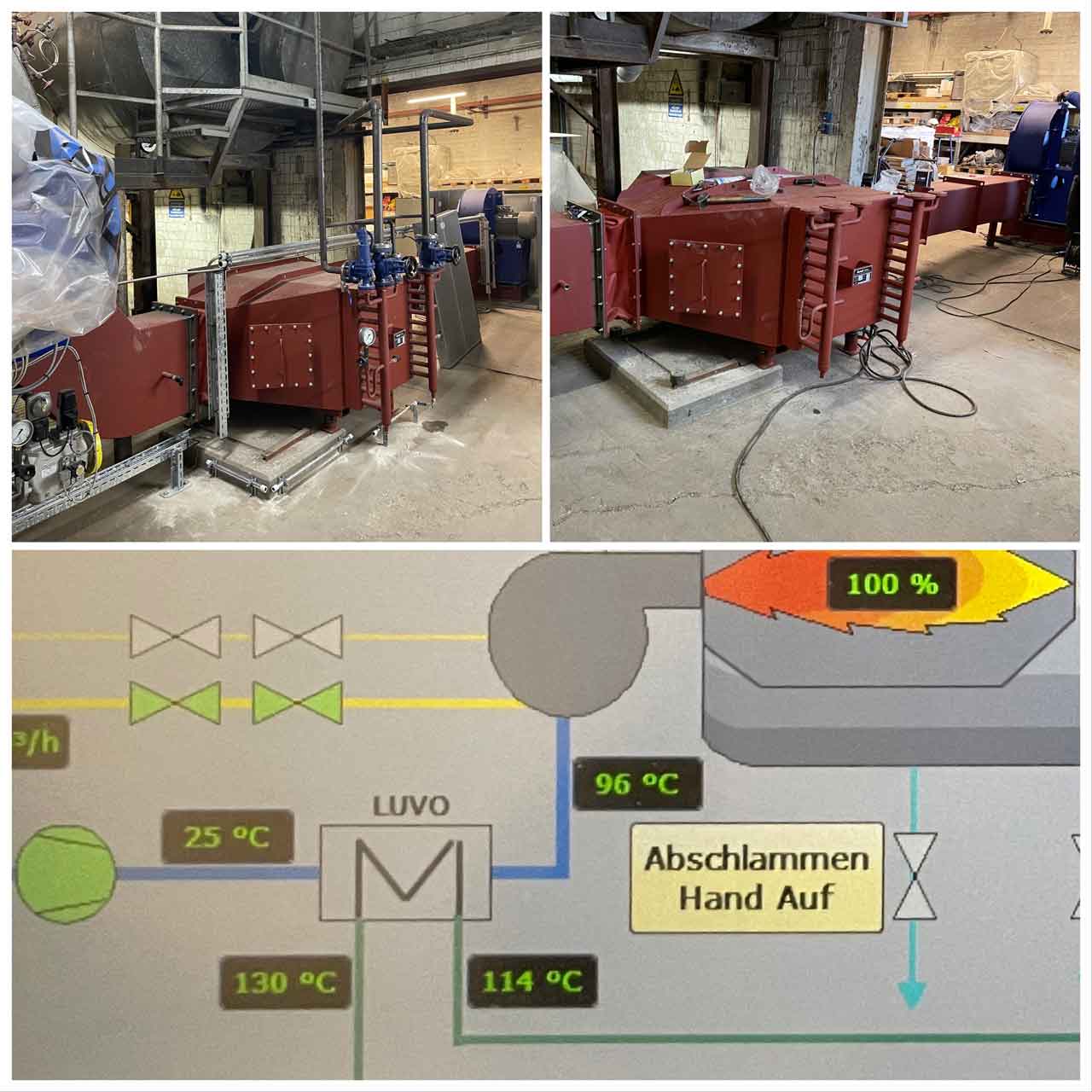

Heating of combustion air from 25°C to 90°C by Boiler feed water.

Heating of combustion air from 25°C to 90°C by Boiler feed water.

The previous heat exchanger was broken after 15 years had to be replaced.

The previous heat exchanger was broken after 30 years had to be replaced.

Essert Energiesparsysteme GmbH & Co KG

Rennstieg 6, D - 47802 Krefeld